CORE PRODUCT

Home> CORE PRODUCT> Pallet conveying system

Pallet conveying system

Pallet conveying system

Toothed belt conveyors

Belt conveyor

Accumulation chain conveyors

Flat top chain conveyor

Roller conveyors

Pallets

Transverse conveyor unit

Curve

Positioning unit

Rotate unit

Lifter

Transportation control

Comprehensive supporting services

Comprehensive supporting services

Whole line planning

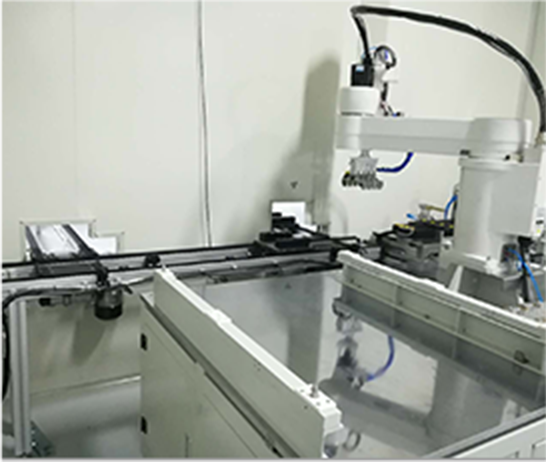

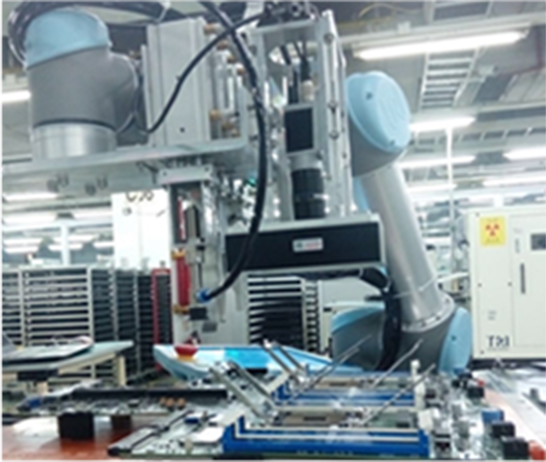

Loading and unloading of the manipulator

Tooling design and processing

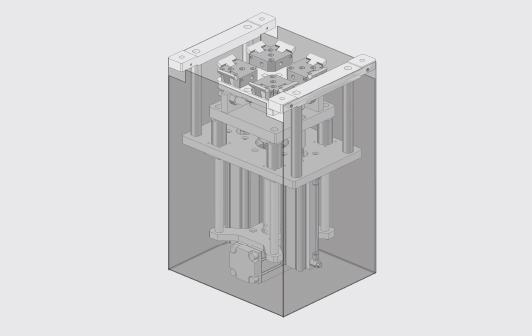

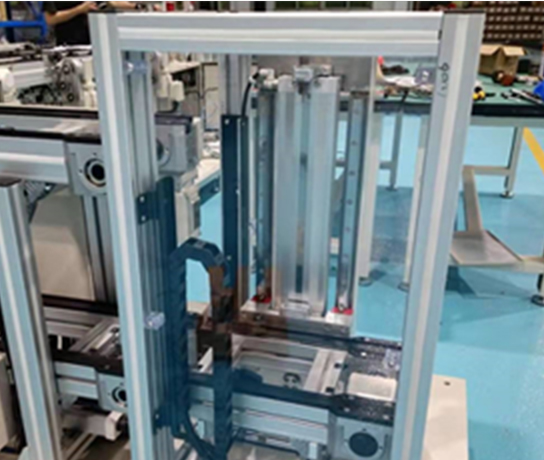

Lift unit

Material caching appliance

Air conveyor platform

Dust cover

Dust removal device

High temperature conveying

Electrical standardization

Other non-standard conveying devices

On-site construction

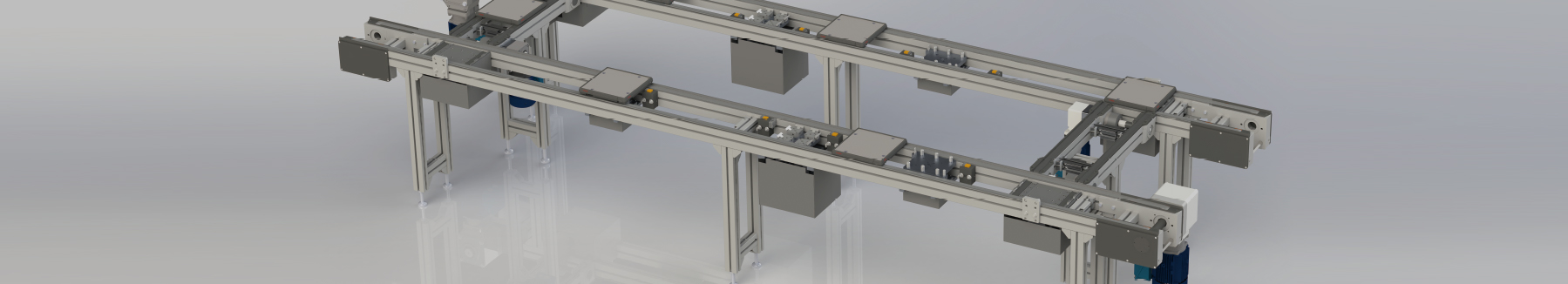

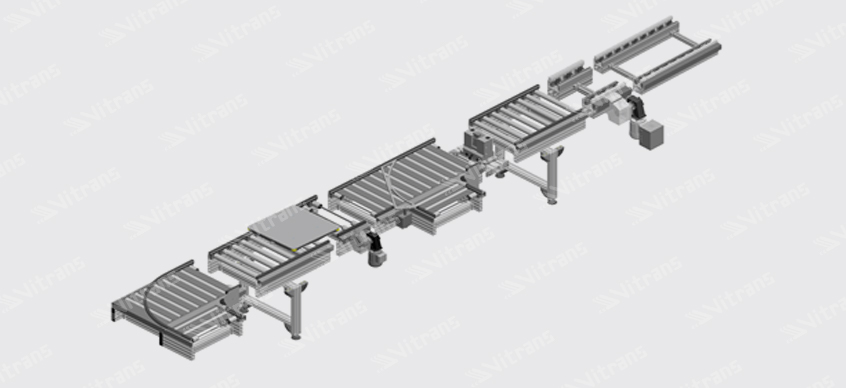

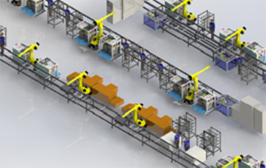

Modular pallet conveying system

The modular pallet conveyor system covers accumulation chain conveyors, flat belt conveyors, and flat top chain conveyors

Machines, , light load and heavy load roller conveyors, according to different loads, applications Environment and size are selected

Toothed belt conveyors

Belt conveyor

Accumulation chain conveyors

Flat top chain conveyor

Roller conveyors

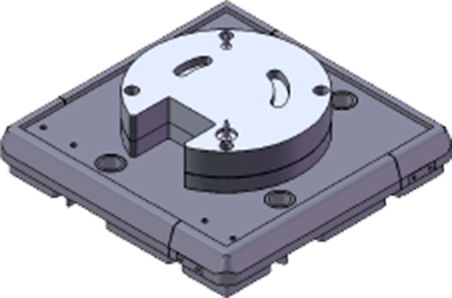

Pallets

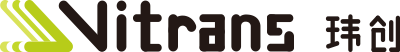

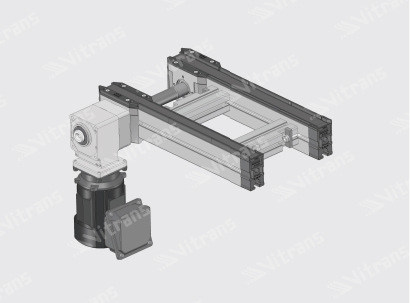

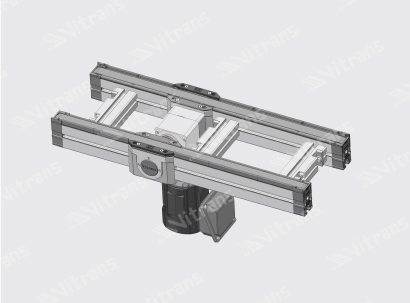

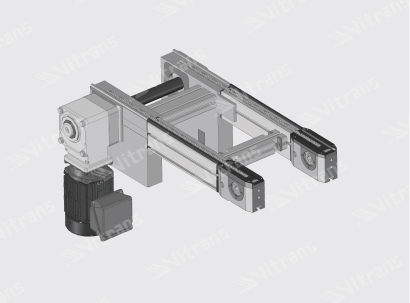

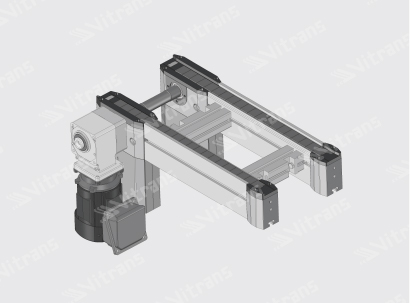

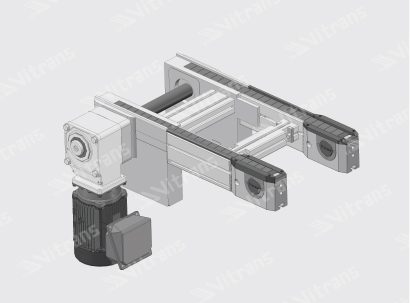

Transverse conveyor unit

Curve

Positioning unit

Rotate unit

Lifter

Transportation control

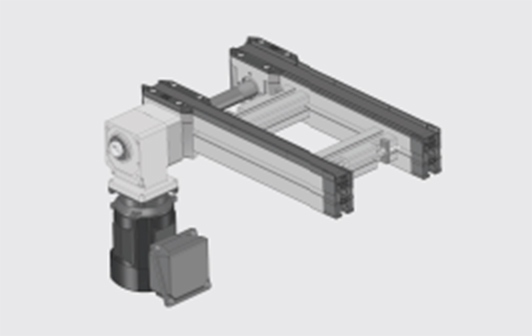

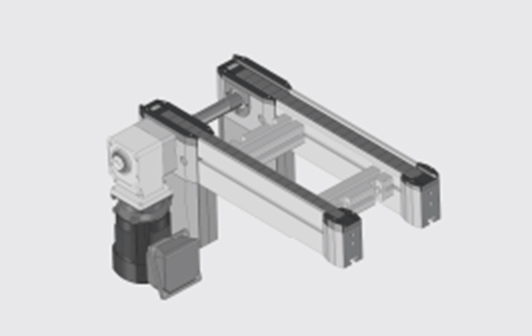

Toothed belt conveyors

Toothed belt conveyor, single section load capacity ≤ 60KG, suitable for light and light load conveying. With the hoist, it can form a double-layer belt conveyor line to achieve reciprocating conveying; With the transverse conveyor unit,it can be composed of circular conveying Feed belt to achieve return conveying. With the characteristics of smooth, dry, clean and low noise, it is widely used in automotive electronics assembly,New energy battery cell assembly logistics line.

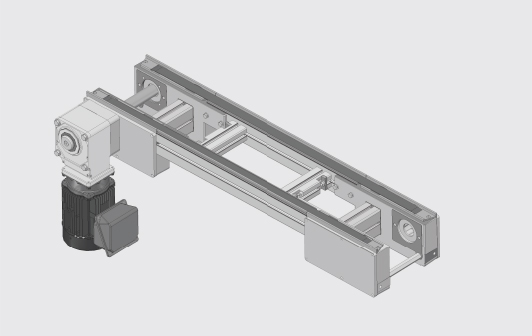

Belt conveyors

Belt conveyor is a kind of conveyor line with strong load capacity in belt conveying system, with a single load capacity of ≤ 250KG, suitable for medium load conveying. With the hoist, it can form a double-layer belt conveyor line to achieve reciprocating conveying; With the transverse conveyor unit, it can form an annular conveyor belt to achieve return conveying. It is stable, dry, clean and low noise Features, widely used in automotive electronics assembly, new energy battery cell assembly logistics line.

Accumulation chain conveyors

The accumulation chain conveyors, contains a triple The accumulation chain conveyors, 2.5 times accumulation chain conveyors and a single accumulation chain conveyor. The accumulation chain conveyors referred to here is a single-speed conveyor (triple accumulation chain conveyors and 2.5x accumulation chain can also be consulted). The single-stage load capacity ≤2200KG, which is suitable for heavy load transportation. With the lifter, it can form a double-layer accumulation chain assembly line to achieve reciprocating transportation; With the transverse conveyor unit, it can form an annular conveyor belt to achieve return conveying.

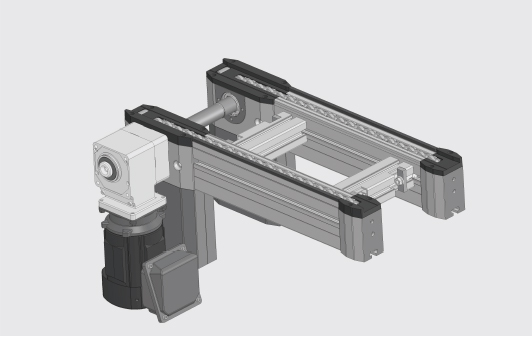

Flat top chain conveyors

Flat top chain conveyor, single section load capacity ≤ 700KG, suitable for medium load conveying. With the hoist, it can form a double-layer pallet assembly line to achieve reciprocating transportation; With the transverse conveyor unit, it can form an annular conveyor belt to achieve return conveying.

Roller conveyors

Roller conveyors, include single and double chain roller conveyors (suitable for light loads) and bevel gear accumulation conveyors (suitable for heavy loads). The roller conveyor referred to here is a bevel gear type accumulation conveyor (single and double chain roller conveyors can also be consulted). The single-stage load capacity can reach more than 4 tons, which is suitable for heavy-duty transportation. With the transverse conveyor unit, it can form an annular conveyor belt to achieve annular return conveying. Suitable for automobile production line assembly line, new energy lithium battery PACK line and module line.

E-mail/E-mail: info@vitrans.cn (Head Office)

Info.sz@vitrans.cn (Shenzhen Office)

info.wx@vitrans.cn (Wuxi Office)

Tel/Head Office Tel: (+86) 0769-8379 1839

Fax/Head Office Fax: (+86) 0769-8379 1839

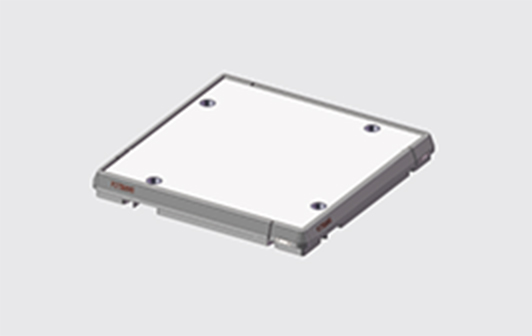

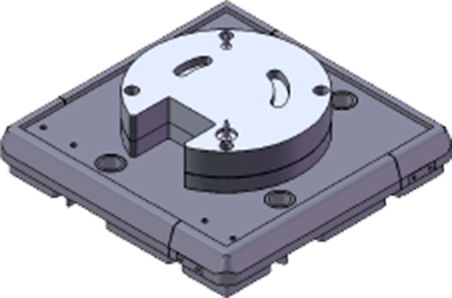

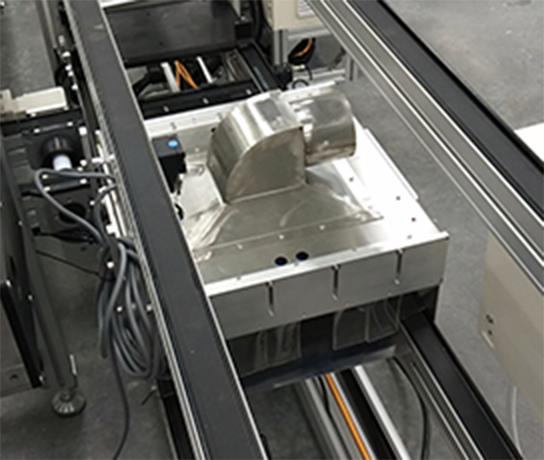

Pallets

he pallets is an indispensable bearing medium for the pallet conveyor. The pallet size can be extended from 160mm*160 mm to 1200mm*1200mm size (larger than this range can be customized beyond standard, welcome to inquire), and the product size is applicable to a wide range. The load plate on the pallet can be installed as a pallets fixture by customer-specific machined holes. The pallet is characterized by high wear resistance.

Transverse conveyor

The transverse conveyor unit is also known as the jacking traverse unit.With the linear section conveyor line can be formed into an annular conveyor belt to achieve backflow transportation.

.png)

ET 2/S Transverse conveyor

The motor is mounted on the side of the conveyor line,

freeing up the bottom position and the multi-layer wire

body environment

.png)

ET 2/T Transverse conveyor

Conveyor section environment with 2 ET 2/S units integrated,

small spacing side by side

.png)

EH 2/S Transverse conveyor

The motor is located under the traverse unit in a single-layer

wire environment

.png)

ET 2/SE Transverse conveyor

Integrated by ET 2/S and a section BC 2 conveyor line

.png)

ET 2/TF Transverse conveyor

Integrated by ET 2/S and a section BC 2 conveyor line

Curves

A curve is also called a turn. It can be combined with a straight conveyor line to form a circular conveyor line to realize reciprocating backflow transmission.

.png)

KV/90 Turning unit

With independent drive unit, drive round belt to complete 90 ° turn

.png)

KV/180 Turning unit

With independent drive unit, drive round belt to complete 180 ° turn

.png)

CV/90 Turning unit

With independent drive unit, drive the plastic flat top chain to complete the 90 ° turn

.png)

CV/180 Turning unit

With independent drive unit, drive the plastic flat top chain to complete 180 ° turn

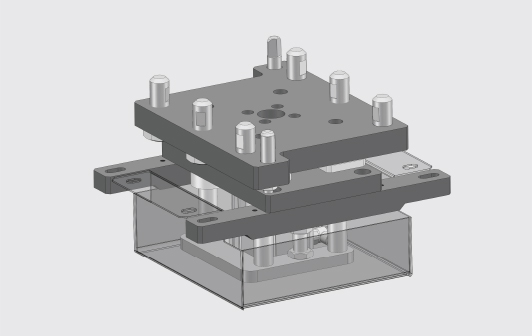

Positioning unit

The jacking positioning unit enables precise positioning of the pallets pallet and realizes the high-precision conveying of the assembly line. The jacking positioning unit is a prerequisite for precision conveyor lines.

Rotate unit

The lifting rotary unit allows the tooling tray to change direction.

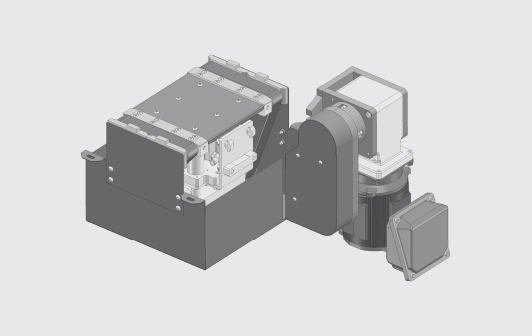

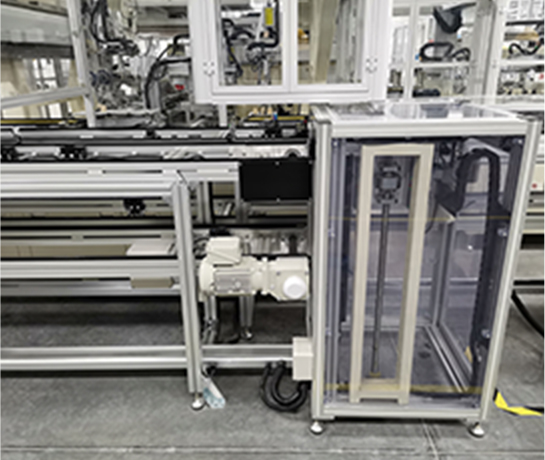

lifter

The lifter and the linear conveyor can form a double-layer pallet conveyor line to achieve reciprocating conveying.

LP/P rodless cylinder hoist

Rod cylinder hoist, lifting power driven by rodless cylinder is suitable for double layer wire, cost-effective, and the cycle time requirements are not high (lifting speed up to 300mm/s) working conditions

.png)

LP/S lead screw hoist

Lead screw elevator, lifting mechanism driven by servo motor is suitable for double or multi-layer wire body, the cycle time requires fast (lifting speed up to 500mm/s) working conditions

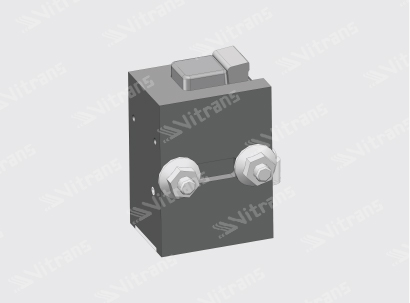

Transportation control

The conveying control element includes a stopper, a cushioning stopper and a stopper for controlling the transmission of pallets on the conveyor line, including functions such as stopping, separation, position sensing and control.

SG stopper

Jacking rotation unit that rotates in the same direction all the

time (can be reset individually)

The rotation angle is 90°

SG/D buffer stopper

Pneumatic control start-stop, with cushioning cylinder,

in a certain range of shock absorption effect

SG/R check holder

No control, comes with a one-way blocking effect,

can effectively eliminate the pallet return trip

Comprehensive supporting services

Comprehensive supporting services cover the whole line planning, manipulator loading, tooling design and processing, liter Descending device, material caching device, air conveyor platform, dust cover, dust removal device, high Temperature conveying, electrical standardization, other non-standard conveying devices and on-site construction.

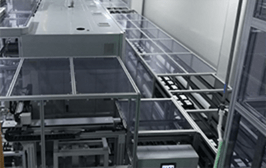

Whole line planning

Loading and unloading of the manipulator

Tooling design and processing

Lift unit

.png)

Material caching appliance

Air conveyor platform

Dust cover

Dust removal device

High temperature conveying

Electrical standardization

Other non-standard conveying devices

On-site construction

Whole line planning

Vitrans's sales engineers can participate in the customer's whole line planning and design in the early stage of the project, and we can provide the

corresponding conveying scheme according to the customer's process flow and specific requirements. The services include:

Wait...... We only want to do more for our customers!

E-mail/E-mail::info@vitrans.cn(Head Office)

Info.sz@vitrans.cn(Shenzhen Office)

Info.wx@vitrans.cn(Wuxi Office)

Tel/Head Office Tel: (+86) 0769-8379 1839

Fax/Head Office Fax: (+86) 0769-8379 1839

Loading and unloading of the manipulator

The manipulator is a device to realize the docking of the conveyor line and the material of the special machine equipment, so that customers can more thoroughly focus their time and energy on the special machine equipment, and the rest is handed over to Vitrans. The Vitrans team can solve the problem from analysis, design, production to installation and commissioning. The service covers a wide range of robots, gripper jaws and their electrical controls.

Three-axis manipulator and gripper jaw

Four-axis manipulator and gripper jaw

Six-axis manipulator and gripper jaw

Tooling design and processing

Tooling design and processing is a necessary guarantee for the pallet conveyor to achieve high-precision conveying positioning of products. Vitrans team combines the manipulator grasping method, product positioning analysis, positioning mode, etc., to ensure the positioning accuracy required by customers. Rapid Changeover (SMED) is a necessary requirement for future automation, and the Vitrans team will also incorporate compatibility with a variety of products into the design idea in the tooling design stage.

Electronics tooling

Auto parts tooling

Lift unit

The lift device is a necessary device for the complete line layout, which can realize the reciprocating and returning flow of the pallet. Vitrans's lift equipment covers rodless cylinder lifts, lead screw lifts, continuous lifts, heavy-duty lifts, arch bridge lifts, high lifts, etc.

Rod cylinder lift

Lead screw lift

Continuous lift

Arch bridge lift

Heavy duty lifts

High lift

Material caching appliance

Material caching device, also known as NG caching device, is generally used in the field of new energy battery transportation. The material caching device can be customized according to the customer's requirements of the cache combing.

E-mail/E-mail: info@vitrans.cn (Head Office)

Info.sz@vitrans.cn (Shenzhen Office)

Info.wx@vitrans.cn(Wuxi Office)

Tel/Head Office Tel: (+86) 0769-8379 1839

Fax/Head Office Fax: (+86) 0769-8379 1839

Air conveyor platform

The air conveyor platform can ensure that the conveyor is transported between different workshops, and can be customized according to the customer's specific height and layout, and can be used with a high-position elevator.

Air transport steel platform

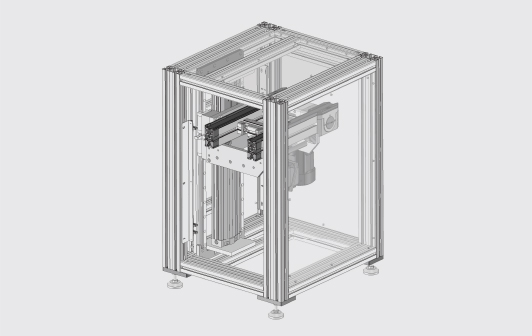

Dust cover

The dust cover is an indispensable part of the conveyor in the clean workshop, and Vitrans uses aluminum profiles and acrylic plates as the main body to achieve both beautiful and cost-effective results.

Dust cover

Dust removal device

The dust collector cleans the tooling tray. Since the pallet and tooling are in direct contact with the product, in order to ensure the cleanliness of the product production environment, the dust removal device has become a necessary device.

Dust collection device model diagram

Physical drawing of the dust removal device

High temperature conveying

High temperature conveying has a wide range of applications in the field of auto parts and new energy battery baking, and Vitrans can achieve up to 180 °C conveying in the field of high temperature transportation.

120°C high temperature transportation

150 °C high temperature conveying

The entrance and exit of the high temperature furnace

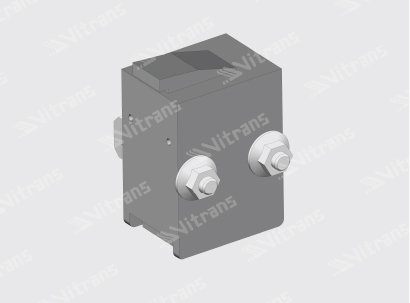

Electrical standardization

Vitrans has achieved standardization in the electrical aspect, covering the standardization of consumables and the standardization of wiring, so as to realize the modularization of electrical wiring. Electrical standardization can greatly improve the aesthetics of the whole line, reduce the wiring time and error rate of on-site construction.

Dust collection device model diagram

Other non-standard conveying devices

Vitrans can also customize non-standard conveying devices according to the specific needs of customers

Rotor conveyor line for automotive motors

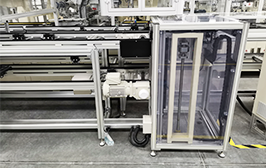

On-site construction

In order to minimize the energy and time of customers, all of Vitrans's conveyor products provide on-site construction services for customers.

On-site construction

.png)

.png)

.png)

.png)

.png)